Page 3 of 5

Posted: November 30th, 2007, 2:00 am

by DollarBill

I'm really proud of myself on this one:

Ok. First, a quick intro. So, this first picture is of the metering block for my Carburetor. It's what allows the proper amount of fuel flow from the fuel bowls. That thing in the middle that looks like a four-sided, corner-less bolt head is called a Power Valve.

SO! I was supposed to torque that power valve to 100 inch/pounds of torque. The problem is, I didn't have a socket (for my torque wrench) that fit around the power valve, and I didn't feel like buying one. But I did have this:

Ok, but how can I know for sure that

I'm pulling the monkey wrench at exactly 100 in/lbs? Well 100 in/lbs is about 8 foot/lbs. The wrench is about 1 foot long. And this is about exactly 8 pounds:

Then you just have to watch your feet:

Posted: November 30th, 2007, 2:12 am

by beardedlamb

fail

Posted: November 30th, 2007, 10:07 pm

by Matt

Bill, the engineer in me wants to hug you right now.

Posted: November 30th, 2007, 11:10 pm

by bradisntclever

Matt wrote:Bill, the engineer in me wants to hug you right now.

Word. That's pretty damn funny.

Posted: February 24th, 2008, 6:12 pm

by beardedlamb

bill, you're failing behind bad on the mod front.

where you at?

beard

Posted: February 25th, 2008, 9:18 pm

by arclight

DollarBill wrote:I'm really proud of myself on this one

So am I, Bill, so am I...

Seriously, I love an elegant engineering hack. Simply brilliant...

Posted: February 27th, 2008, 10:44 pm

by DollarBill

beardedlamb wrote:

where you at?

beard

INDOORS!!!!

Here's a current picture of the garage where my car is.

Posted: February 28th, 2008, 12:54 am

by arclight

I never want to have to shovel that shit again for as long as I live.

Fuck snow.

Posted: February 28th, 2008, 3:36 pm

by beardedlamb

i used to have a matress in that garage and lots of paint cans that madeline wanted me to pick up from a free craigslist post. are they still in there?

Posted: May 31st, 2008, 2:32 am

by DollarBill

IT'S WARM!!! FINALLY!!!!!! So I'm back on the job, trusty head-lamp and all.

The next hurdle is to get the engine started for the first time in like 5 years. I drained the oil and coolant and I have a long list of other things to do, but before I get to that I need to rectify a problem I caused 6 years ago. I put on a new intake manifold, and in the process, snapped one of the intake bolts off in the cylinder head. So since I'm tearing stuff apart I figured I may as well replace those bolts. Here's a normal one next to the broken one:

So here's what I started with today:

Then I took this stuff off:

And I ended up with this:

Now I have to get a left-handed drill bit and/or and "easy-out" bit to drill into the broken bolt stud so that I can get it out of there. I guess I'll have to buy or borrow a drill since Ace ruined his like he does everything else in his life.

What I effed up: Well there were some mud-dauber nests I didn't see and some of the chunks of dirt got into the engine. Way down where my fingers can't get to. So I don't know what I'm gonna do about that yet. Hm. If I just extrapolate that feeling across the rest of my day, I think I know what it's like to be Ace. Is there a sad poem about mud-dauber dirt gumming up the cam gears of your life engine?

Posted: June 2nd, 2008, 1:11 pm

by DollarBill

OK! So. Dirt in the engine. Not good. But, while I was in the shower (sorry, no pics) I thought of the solution. SUCTION! Then my brother in law called and told me I could also try flushing it out with WD-40. So, I thought I'd do both. Suck out the big stuff and flush the dust to be safe.

Here's the offending chunks. you can kinda see the dirt down in the hole in the center of the pic:

The problem is fitting a vacuum in there. So I MacGyvered an attachment for our dustbuster out of a straw, some tape, and an existing attachment.

Here it is, in action. It worked like a charm. And after a healthy dose of WD-40, everything is all clean and, after I get that broken bolt stud out, ready for reassembly.

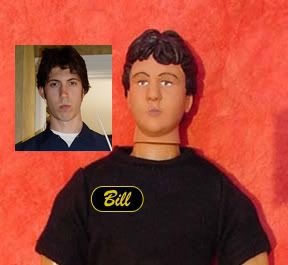

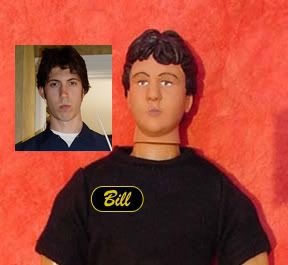

If they ever make an action figure of me, hopefully there will be a Bendy-Straw-Dust-Buster-Bill:

Posted: June 3rd, 2008, 3:06 pm

by DollarBill

So I "learned" some more things this morning. Which means I screwed up a lot until I figured it out.

1) When you are extracting a bolt stud that you can't grip with pliers, you gotta drill a hole and then use a drill bit with threads that go counter clockwise to extract it. Well, if you don't drill right in the center of the bolt a lot of bad things happen. You can ruin the threads of whatever your bolt is stuck in, and it makes it harder to extract because your torque isn't centralized anymore...

2) Lube. There's a ton of different loosener sprays for parts that are stuck. I still have a can of PB BLASTER! It's what the guy at autozone in Austin told me was the best stuff. It's definitely the most fun to say.

3) If you're choosing between extraction bit sizes, go with the smaller size first. Actually, just go ahead and buy a whole set so that you don't have to go back to the store while weird storm sirens are going off that make you wonder if you should have put on real shoes instead of flip flops in case you need to run from a tornado... yes I am that fast.

IT'S ALWAYS BEST TO HAVE THE RIGHT TOOL FOR THE JOB. Remember that. Especially when you see one of those miracle-all-in-one tools on the TV. Plus it's just cool to have tools. It rhymes. It must be true. That's why I bought a new drill!

Left: The hole on the right is the one with the stuck bolt stud.

Middle: PB BLASTER, New drill, and extractor bit with the unstuck broken bolt on the end.

Right: Unstuck bolt stud next to full sized for comparison.

Posted: June 30th, 2008, 5:16 pm

by DollarBill

Ok, y'all... ... who is "y'all"? Does anyone actually read this? Doesn't matter. It's more of a diary anyway.

Anyway. I'm back on track. I was at a standstill for a while because I couldn't get the right bolts for my intake manifold. Ford has produced some form of the engine in my car from 1969 to the present. Turns out in '69 and '70 they used a different set of bolts for the intake manifold.

I wanted to get new bolts so that I didn't snap any more of them off in the heads like in the above post. Every place sells the standard set of 12 bolts that are 2" long, but nobody sells 16 that are 2-1/4" long. I consulted some friends and some message boards and was told to just buy grade-8 bolts and washers that were the right size. Guess what! None of the hardware stores around here sell Grade-8 5/16-18 bolts that are 2-1/4" long...

BUT! Luckily an old school Well Hung Jury member was in town visiting me. He got his masters in physics and has worked on all kinds of crazy lasers and rail guns and lab equipment that needs specialty hardware. He showed me THE GREATEST WEBSITE IN THE WORLD!!!!!!!

McMaster-Carr

www.mcmaster.com HOLY CRAP! They have everything! They had the exact bolts I needed, and I didn't even have to get washers cuz they had em in flange head!!!!!! I'm back on track, and I'm hoping to try and start the engine for the first time in many years this weekend. I know it probably won't work, but at least I'm almost at the point where I can try.

Posted: June 30th, 2008, 5:53 pm

by improvstitute

I read it...

Posted: June 30th, 2008, 7:04 pm

by mcnichol

DollarBill wrote:Ok, y'all... ... who is "y'all"? Does anyone actually read this?

I'm still here! I love reading this thread Bill!