So I "learned" some more things this morning. Which means I screwed up a lot until I figured it out.

1) When you are extracting a bolt stud that you can't grip with pliers, you gotta drill a hole and then use a drill bit with threads that go counter clockwise to extract it. Well, if you don't drill right in the center of the bolt a lot of bad things happen. You can ruin the threads of whatever your bolt is stuck in, and it makes it harder to extract because your torque isn't centralized anymore...

2) Lube. There's a ton of different loosener sprays for parts that are stuck. I still have a can of PB BLASTER! It's what the guy at autozone in Austin told me was the best stuff. It's definitely the most fun to say.

3) If you're choosing between extraction bit sizes, go with the smaller size first. Actually, just go ahead and buy a whole set so that you don't have to go back to the store while weird storm sirens are going off that make you wonder if you should have put on real shoes instead of flip flops in case you need to run from a tornado... yes I am that fast.

IT'S ALWAYS BEST TO HAVE THE RIGHT TOOL FOR THE JOB. Remember that. Especially when you see one of those miracle-all-in-one tools on the TV. Plus it's just cool to have tools. It rhymes. It must be true. That's why I bought a new drill!

Left: The hole on the right is the one with the stuck bolt stud.

Middle: PB BLASTER, New drill, and extractor bit with the unstuck broken bolt on the end.

Right: Unstuck bolt stud next to full sized for comparison.

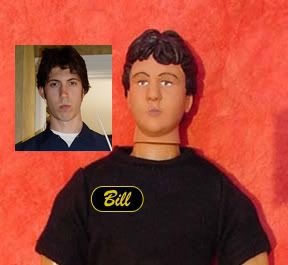

They call me Dollar Bill 'cause I always make sense.